13738608815

13738608815

13738608815

13738608815

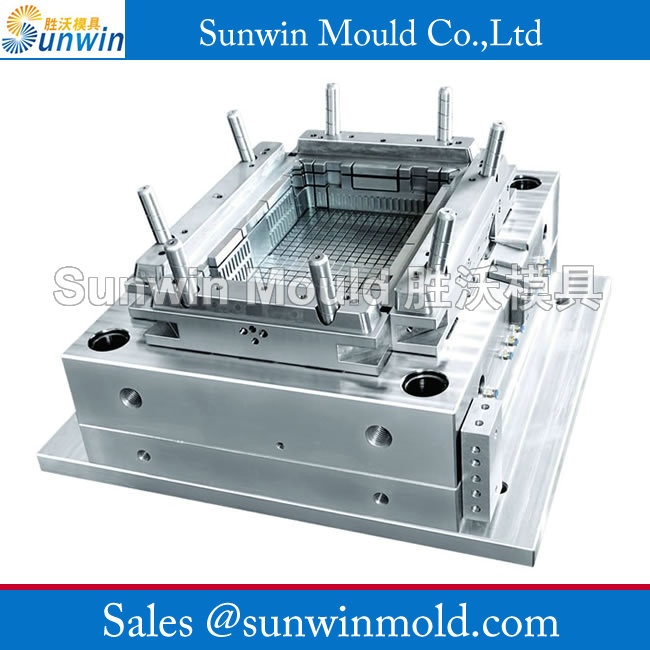

Characteristic for our crate mould

To make a crate mould using long time,

1. we will recommend cavity and core with P20 pre-hardnessHRC33 ,slider with imported Germany 1.2738HH pre-hardnessHRC38

2. we will use 1.2.4 or 6 point hot runner system by your requirement ,you may choose YODU or China local famous brand

3. we will design special good cooling water system to shorten the cycle time and improve the production efficiency,

4. we can design the mold by your plastic injection molding machine, before design ,you have to offer detailed the specification of plastic injection machine. We also can recommend some servo injection molding machine , which can save power 50% than common injection molding machine.

5. For ejection system, our professional mold designer with more than 10 years experience will design smooth mechanical system, we ofen use oil cylinder to pull the slide then eject crate.it is very stable system.

6. We will use precision machine equipment to assure the key dimension and produce high precision mould.

7. With many year experience and technology accumulation ,our team can avoid many product defect, and the mould problem, such sink mark ,pin mark, deformation, shrinkage pool, we also use mold flow software and material HDPE MFI to analysis and help confirm suitable wall thickness to maximize your profit.

Sunwin mould have served for many Chinese plastic crate molding factory, there are many different industrial lines, beer bottle crate mould ,fruit crate mould , fish crate mould , industrial crate mould,milk bottle crate mould, bread crate mould and so on

We will give the best plastic crate molding solutions