+86-13738608815

+86-13738608815

+86-13738608815

+86-13738608815

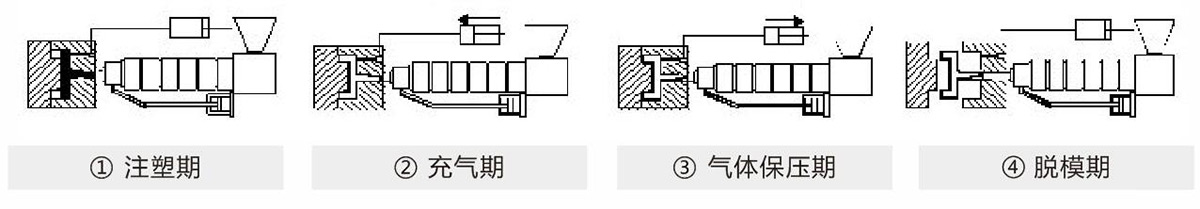

The gas-assisted process is a relatively complicated process. In general, the product is filled first, then the high-pressure inert gas is blown, the raw material in a semi-molten state is blown out, and the gas is used instead of the injection molding machine to obtain the product. Become a gas-assisted molding.

Gas-assisted molding can also be solved by unconventional methods, such as injecting nitrogen into the mold at 70%-80% immediately, and using nitrogen-assisted molding for the filled position. This process is also a conventional process and can be used if necessary.

The number of modules in the gas-assisted mold is mostly 1*1. The number of mold cavities will cause the rubber or the intake air to be unstable. This process is difficult to adjust. When it is produced normally, it will produce a high scrap rate. Therefore, it is generally recommended. Modular cavity structure. If you design a 1+1 mold structure, you need two separate air inlets for the two-point needle valve. Two gas-assisted controllers are required, which will stabilize the product.

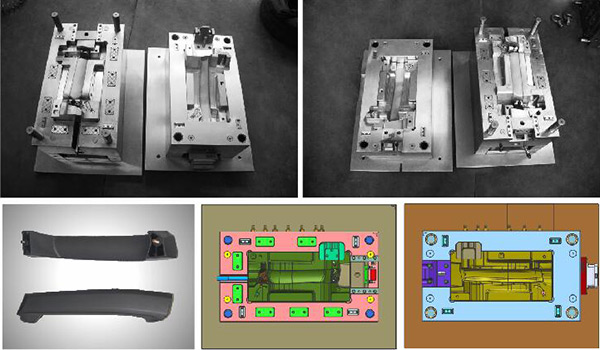

Our main products are kinds of automobile internal and external decoration of plastic mold, household appliances plastic mold and daily necessities. for manufacturing high precision molds.

Add: No. 1 Beiyuan Avenue, Huangyan, Taizhou City, Zhejiang

Tel: +86-13738608815

Fax: +86-0576-84407109

E-mail: [email protected]

Web: www.sunwinmold.com