+86-13738608815

+86-13738608815

+86-13738608815

+86-13738608815

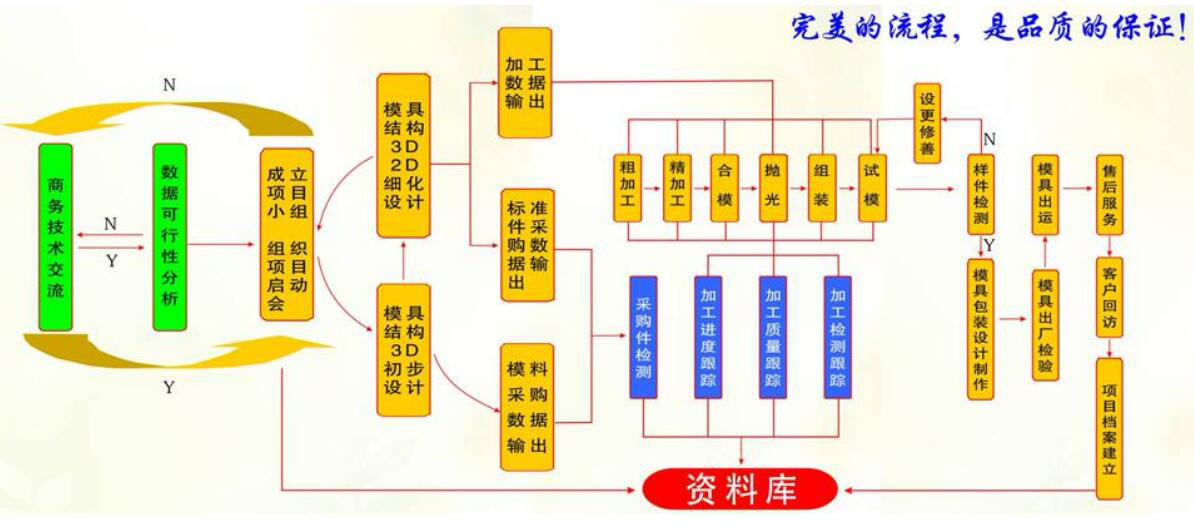

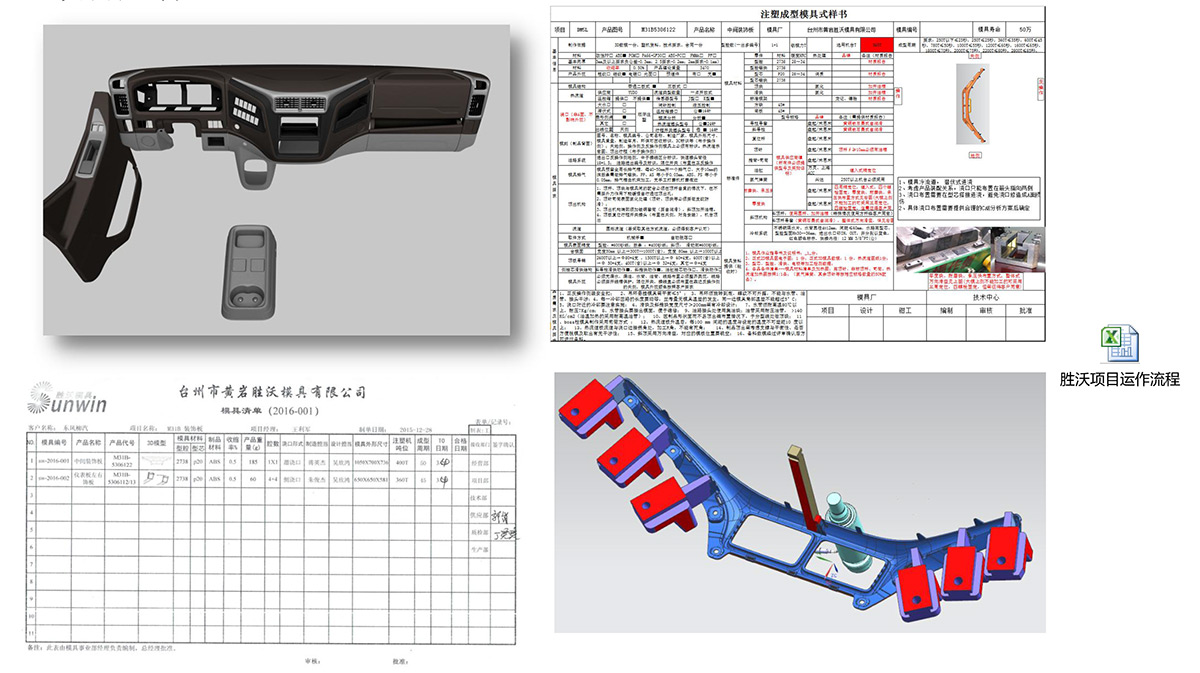

Organize project start-up meeting: understand customer requirements, project list!

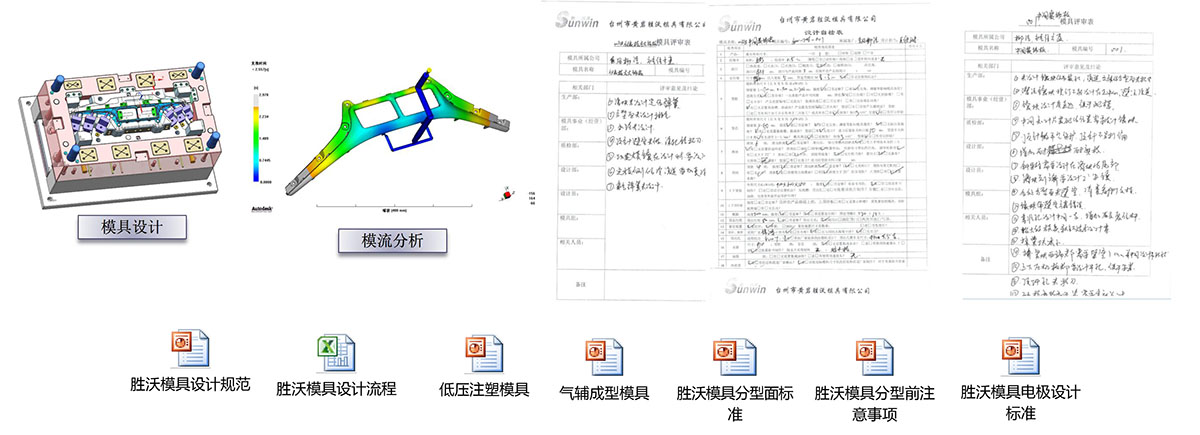

The first stage: preliminary review to establish the direction of the mold structure.

The second stage: the middle review determines the procurement of materials, the roughing begins, and the machining process is arranged.

The third stage: the final review establishes the processing.

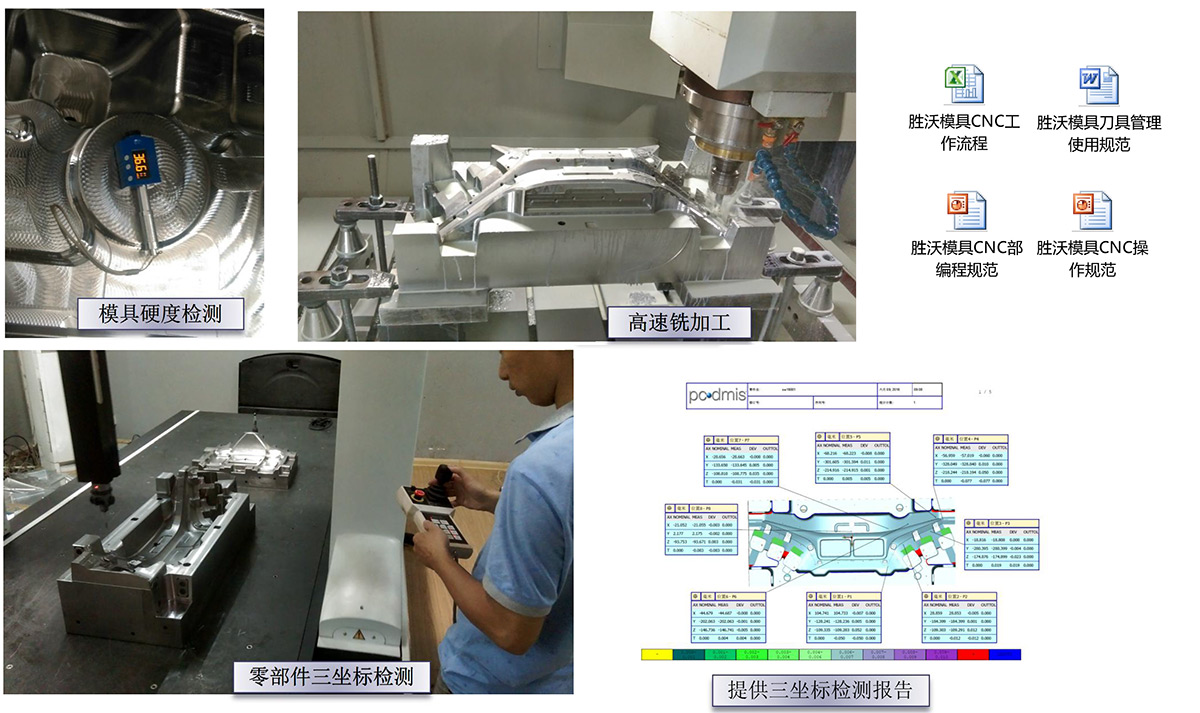

Timely do a good job in the testing of mold processing, unqualified parts to find and correct in time, to avoid the unnecessary cost of mold rework caused by rework!

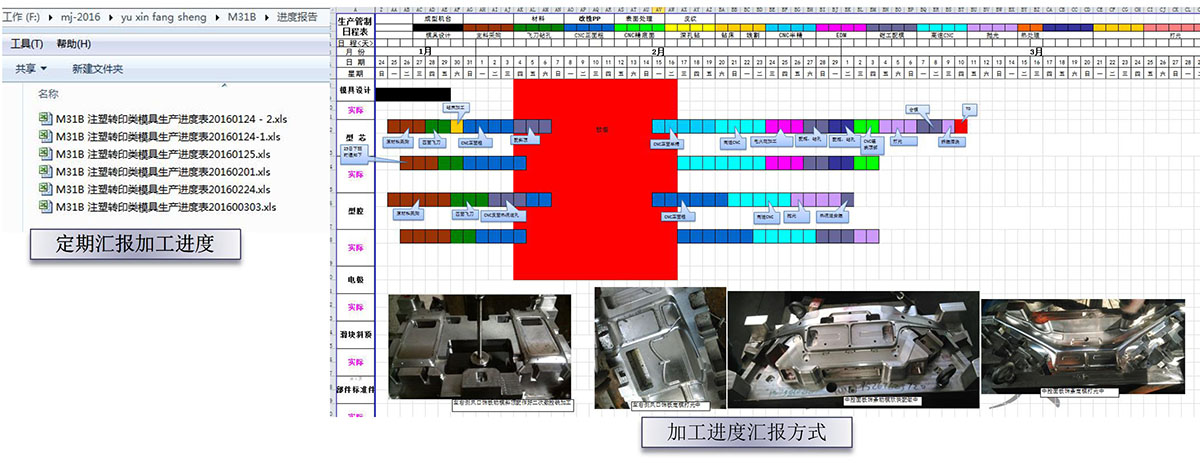

Regularly report the progress of mold processing to customers, so that customers can understand the process of mold processing!

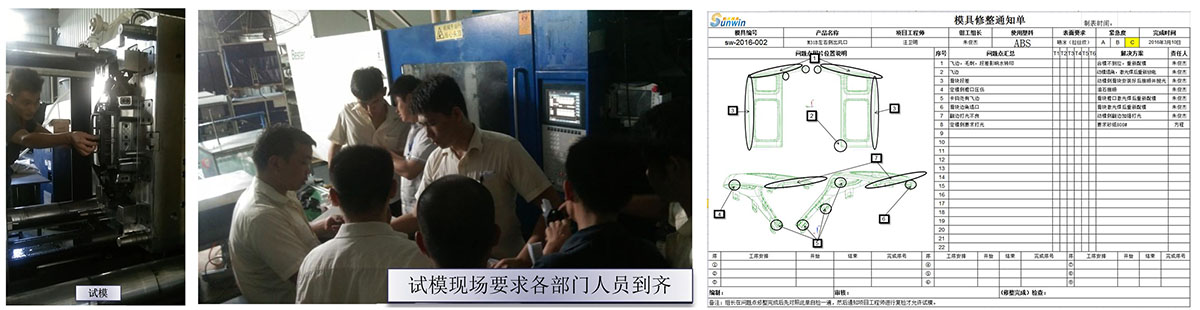

When the mold T1 is tested, all departments are required to arrive at the scene and understand the actual problems, improve the deficiencies of each department, and implement the mold correction work in time!

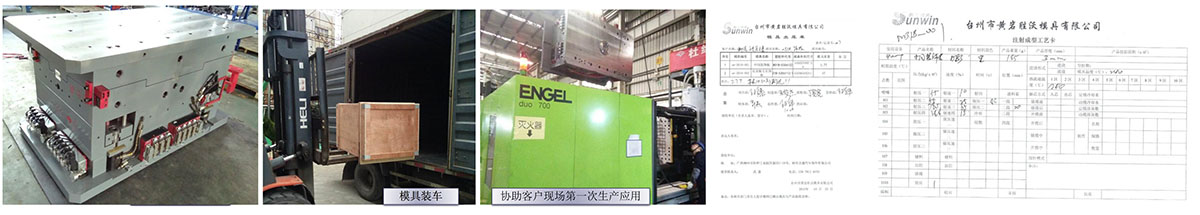

According to the customer's requirements, the molds are prepared, ready to be shipped, and the engineers are dispatched to deliver the molds on-site to help customers smoothly use the molds to produce products!

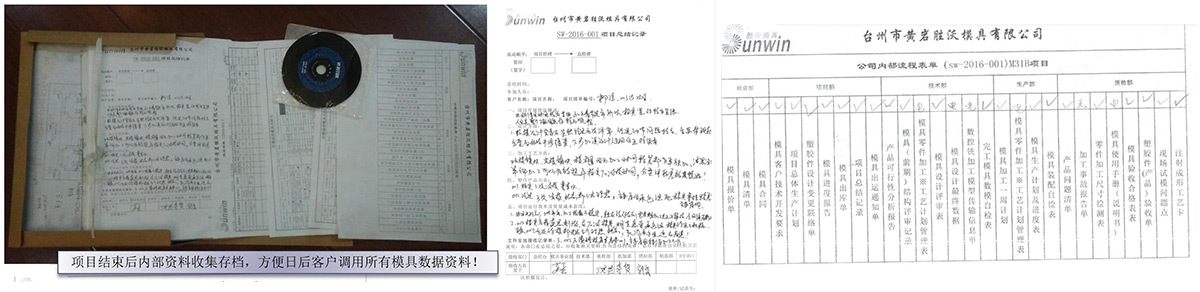

Summarize the problems in the operation of the project, find out the inadequacy of the company's operation, and sort out the final data, so that customers can consult it when they use it!

Our main products are kinds of automobile internal and external decoration of plastic mold, household appliances plastic mold and daily necessities. for manufacturing high precision molds.

Add: No. 1 Beiyuan Avenue, Huangyan, Taizhou City, Zhejiang

Tel: +86-13738608815

Fax: +86-0576-84407109

E-mail: [email protected]

Web: www.sunwinmold.com